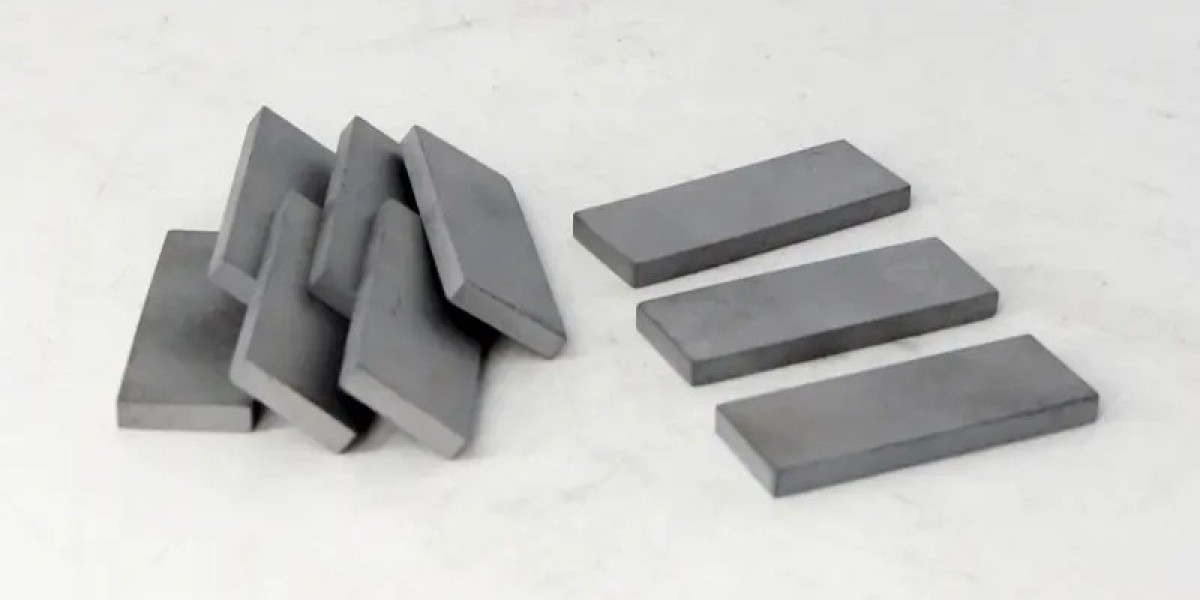

In the demanding world of industrial applications, the need for high-performance wear parts is crucial. ZGJRDCC has established itself as a leading manufacturer of tungsten carbide wear parts, providing solutions that excel in performance and durability. This article explores how ZGJRDCC meets the rigorous demands of industrial Tungsten Carbide Wear Parts Manufacturers applications through its high-quality tungsten carbide wear parts.

The Significance of Tungsten Carbide in Industrial Applications

Tungsten carbide is renowned for its exceptional hardness, wear resistance, and durability. These properties make it an ideal material for wear parts used in challenging industrial environments. Here’s why tungsten carbide is the material of choice:

Superior Hardness and Wear Resistance

- Durability: Tungsten carbide's high hardness ensures that wear parts can withstand extreme conditions and abrasive forces, extending the service life of equipment.

- Performance: Components made from tungsten carbide maintain their integrity and performance even under high-stress applications, reducing the frequency of replacements and downtime.

High-Temperature Tolerance

- Thermal Stability: Tungsten carbide retains its properties at elevated temperatures, making it suitable for applications that involve heat or thermal cycling.

- Resistance to Deformation: The material’s resistance to deformation under high temperatures helps maintain precision and functionality in demanding environments.

ZGJRDCC’s Approach to High-Performance Wear Parts

ZGJRDCC’s commitment to delivering high-performance tungsten carbide wear parts is reflected in its advanced manufacturing processes, stringent quality control, and dedication to innovation.

Advanced Manufacturing Techniques

- Premium Material Selection: ZGJRDCC sources high-quality tungsten carbide powders to ensure that its wear parts have superior hardness and wear resistance. The selection of materials is crucial for achieving the desired performance and durability.

- Precision Sintering: The company uses state-of-the-art sintering technology to control temperature and pressure with high accuracy. This process creates a dense, homogeneous material that enhances the wear parts’ performance.

Cutting-Edge Machining and Design

- CNC Machining: ZGJRDCC employs advanced Computer Numerical Control (CNC) machining to achieve precise dimensions and complex geometries. This technology ensures that each wear part meets exact specifications, contributing to overall performance and reliability.

- Innovative Design: The company’s engineering team designs wear parts with a focus on optimizing functionality for specific industrial applications. This includes incorporating features that enhance performance in high-stress environments.

Rigorous Quality Control

- In-Process Monitoring: ZGJRDCC implements real-time monitoring during production to maintain consistency and precision. Any deviations from standards are promptly addressed to ensure high-quality output.

- Final Testing: Each wear part undergoes comprehensive testing to verify its performance under simulated operational conditions. This rigorous approach ensures that the final product meets the highest standards of quality and reliability.

Applications of ZGJRDCC’s Tungsten Carbide Wear Parts

ZGJRDCC’s high-performance tungsten carbide wear parts are utilized across a range of industrial applications, each with its specific requirements:

Mining and Drilling

- Drill Bits and Reamers: Designed to endure harsh conditions and abrasive materials, ZGJRDCC’s wear parts enhance efficiency and extend the lifespan of mining and drilling equipment.

Construction

- Cutting Edges and Teeth: Custom wear parts for heavy machinery, including cutting edges and teeth, are engineered to handle the rigorous demands of construction environments, providing reliable performance and durability.

Oil and Gas

- Exploration Equipment: Specialized components for drilling and exploration equipment are crafted to withstand extreme pressures and temperatures, ensuring operational reliability in challenging conditions.

Commitment to Customer Satisfaction

ZGJRDCC’s commitment to customer satisfaction is evident in its customer-focused approach and support services:

- Responsive Support: The company provides expert support to address client needs and ensure that wear parts meet specific application requirements.

- On-Time Delivery: ZGJRDCC is dedicated to delivering high-performance wear parts on schedule, helping clients maintain operational efficiency and reduce downtime.

Conclusion

ZGJRDCC has established itself as a leader in the tungsten carbide wear parts industry by delivering high-performance solutions that meet the demanding requirements of industrial applications. Through advanced manufacturing techniques, cutting-edge design, and rigorous quality control, ZGJRDCC ensures that its wear parts excel in performance, durability, and reliability. For industries seeking robust and high-quality tungsten carbide wear parts, ZGJRDCC is the trusted choice for achieving superior results and maintaining operational excellence.