introduce

T-shirts are very common; Let's say you have some shirts hanging in your closet, too. Everyone loves to have a unique short individual, and with the arrival of laser technology, the DIY industry has a new way to make bespoke and personalized T-shirts.

In 2024, people love making their T-shirts, which is why search engines are showing a high trend in queries such as What is a laser engraving machine near me printing and How to convert digital files into T-shirts? Digital designs were used to make such T-shirts. Since personalization is the new trend, many people use digital designs to make T-shirts. All it takes is a little technological improvement here and there to launch the next generation of lasers that turn your digital files into beautiful prints on T-shirts that are both long-lasting and reliable.

However, to continue making T-shirts using laser technology, one should know that it is different from most screen printing or thermal transfer printing. Using lasers, cutting or engraving can be done directly, direct images can be placed on the fabric, and can also be used to help form templates for actual printing on T-shirts. Laser technology is in demand in this segment due to its ultra-fine cutting and higher accuracy than traditional methods. The technique refers to two methods of turning digital files into T-shirt designs:

1. Laser engraving: Use a laser beam to carve patterns directly on the fabric.

2. Laser cutting for heat transfer: Lasers trim vinyl or other heat transfer materials that later heat the T-shirt, leaving a printed imprint on the shirt.

Now that you know the two common techniques, here's how to turn digital files into T-shirts using laser cutters and engraving machines:

1. The first step is a digital design, we recommend browsing Pinterest, Tumblr, etc. to get some inspiration. Next, create your design file with the help of graphic design tools from common tools like Adobe Illustrator and Corel Draw. Make sure your design is not too thin or too complicated for easy printing.

2. After completing the design, load and save it in a format compatible with your laser engraving machine; Most of the time, it will be.SVG or. Dxf. These extensions are designed to ensure that the file sizes and Settings on the engraver reflect the size and details of the shirt.

3. This is crucial: Choose a shirt fabric that can work with a laser beam. The most commonly used materials are cotton and polyester, but other materials are often used in dress shirts. Ensure that the fabric used will not stick, bend, or melt when subjected to heat or laser cutting techniques. Stick to natural fabrics for best results; Cotton or cotton-polyester works best.

4. Check whether the laser engraving machine is compatible with the engraving on the fabric and whether you have set the correct laser engraving machine power and speed. The behavior of each material is unique, so it is important to pre-apply the Settings on the sample material rather than on the T-shirt intended for production. We recommend a thorough study of your fabrics. Once determined, place the shirt smoothly on the laser bed and begin the engraving process.

5. If you use the second technique above for a laser engraving machine near me heat transfer vinyl to print your design, we strongly recommend that you first adjust the laser Settings to that vinyl surface so that the laser can only cut the material cleanly, without burning or melting at the edges.

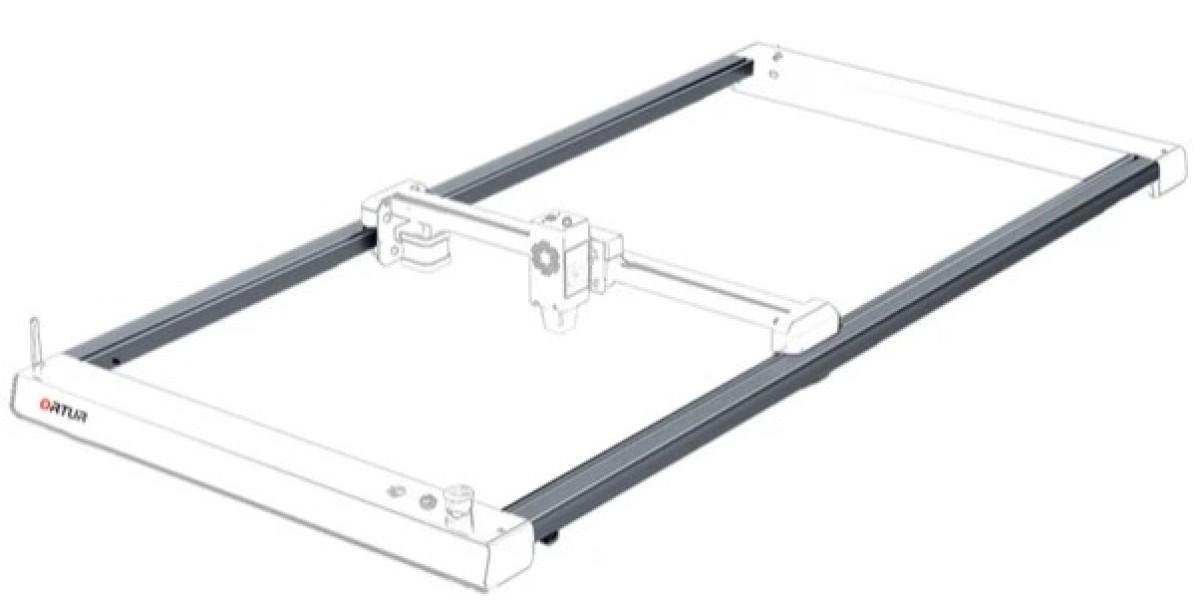

6. When finished, check the T-shirt for any possible defects, cut off any strings hanging around, and other minor problems. These issues can be minimized by using a fabric-compatible laser engraver/cutter and the next generation of future packaging technology, the Ortur H10 laser engraving machine near me. The hardware features an ultra-high precision of 0.01mm and a comprehensive air assist system that ensures you get a smooth cut on the fabric and comes with its own Inspiraesch software that makes the process of designing and engraving any T-shirt design digital file even easier.

Common mistakes and tips/tricks

Now you have a general idea of how to convert digital files into T-shirts using a powerful and compatible laser engraving machine near me and the engraver. Even if you have enough hardware and knowledge, here are the most common mistakes:

1. Thin fabrics, such as silk and rayon, are easily damaged, while other thick fabrics, such as denim, may require high-power lasers. Choose a laser engraving machine near me that matches this type of fabric, or ask the OEM directly.

Alice

29 Blog posts