Amlodipine is a widely used medication in the treatment of high blood pressure (hypertension) and chest pain (angina). As a calcium channel blocker, amlodipine works by relaxing blood vessels, allowing blood to flow more easily and reducing the heart's workload. Due to its efficacy and widespread use, amlodipine is an essential pharmaceutical product in cardiovascular treatment protocols across the globe. Given its high demand and critical role in healthcare, optimizing the Amlodipine Production Cost is essential for pharmaceutical companies to ensure both profitability and accessibility.

Request a Free Sample for Amlodipine Production Cost Reports – https://www.procurementresource.com/production-cost-report-store/amlodipine/request-sample

In this article, we explore the key factors influencing amlodipine production costs and provide insights into how pharmaceutical companies can optimize their production processes for greater efficiency and cost savings.

The Role of Amlodipine in Global Healthcare

Amlodipine is a first-line treatment for hypertension and is often prescribed in combination with other medications to help manage blood pressure and prevent cardiovascular events such as heart attacks and strokes. Its long half-life allows for once-daily dosing, making it a convenient option for patients, which contributes to its popularity in both developed and developing healthcare markets.

The global demand for amlodipine continues to rise as the prevalence of cardiovascular diseases increases due to aging populations and lifestyle-related risk factors such as poor diet, lack of exercise, and smoking. As a result, pharmaceutical manufacturers must carefully manage production costs to meet the growing demand while maintaining affordability for patients.

Key Factors Influencing Amlodipine Production Costs

The cost of producing amlodipine is determined by several factors, including raw material procurement, manufacturing processes, energy consumption, labor, and regulatory compliance. Below, we examine the key cost drivers associated with amlodipine production:

Read the Full Report – https://www.procurementresource.com/production-cost-report-store/amlodipine

1. Raw Material Costs

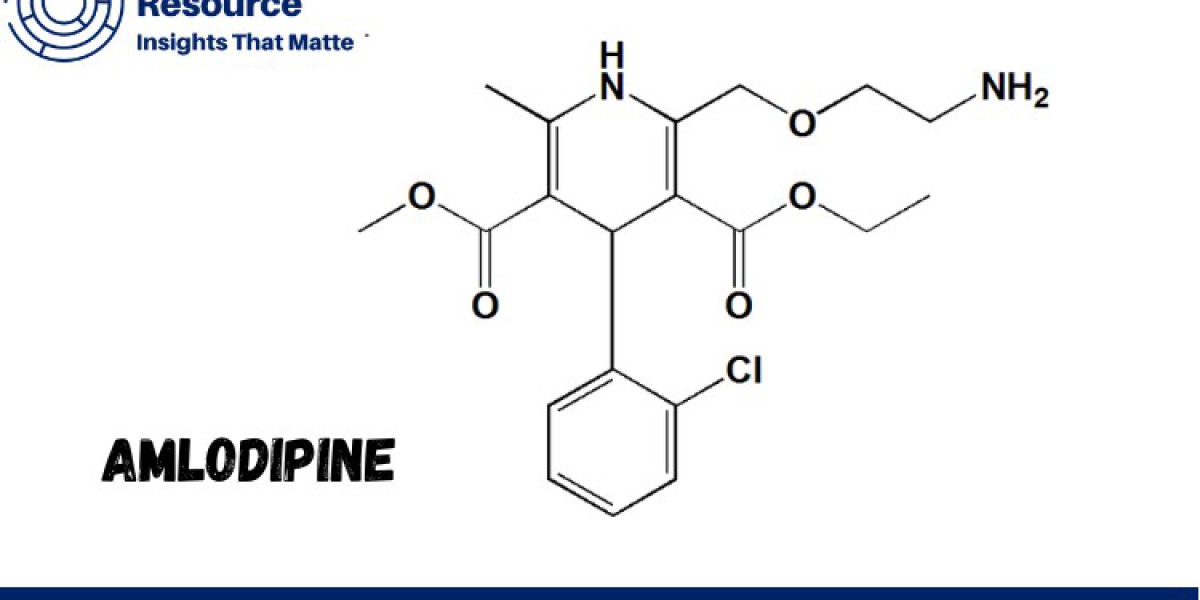

The production of amlodipine involves the procurement of active pharmaceutical ingredients (APIs) and excipients, which must meet strict quality standards to ensure the efficacy and safety of the final product.

Active Pharmaceutical Ingredient (API): The synthesis of amlodipine’s API is complex and involves multiple chemical reactions. The cost of raw materials, including reagents, solvents, and intermediates, can fluctuate based on market conditions, supplier availability, and geopolitical factors. Securing reliable and cost-effective sources of these raw materials is critical for managing production costs.

Excipients: In addition to the API, the production of amlodipine tablets requires excipients such as fillers, binders, and stabilizers. While excipients are generally less expensive than the API, their quality and compatibility with the API are crucial for ensuring the stability and effectiveness of the final product.

Monitoring global raw material markets and optimizing procurement strategies are essential for minimizing production costs and ensuring a consistent supply of high-quality materials.

2. Manufacturing Process Efficiency

Amlodipine is typically produced in tablet form, and its production involves several stages, including API synthesis, formulation, tablet compression, and packaging. The efficiency of each stage significantly affects production costs.

API Synthesis: The chemical synthesis of amlodipine requires careful control over reaction conditions, such as temperature, pressure, and pH levels. Low yields or inefficient reactions can result in higher material costs and increased waste. Optimizing reaction conditions and improving yield efficiency are critical strategies for reducing production costs.

Formulation and Tablet Compression: Once the API has been synthesized, it must be formulated into a tablet using excipients and compressed into the final dosage form. This process requires advanced equipment and precise control over dosage uniformity, weight variation, and tablet hardness.

Coating and Packaging: The final steps in amlodipine production involve coating the tablets (if required) and packaging them in blister packs or bottles. Optimizing these processes can reduce waste and minimize downtime, leading to lower production costs.

Improving manufacturing process efficiency through technological advancements, automation, and process optimization is essential for reducing costs and maintaining product quality.

3. Energy and Utility Costs

Pharmaceutical manufacturing is energy-intensive, particularly during the synthesis and drying processes involved in API production. Energy costs are a significant contributor to overall production expenses.

Energy Consumption: Maintaining the necessary conditions for chemical synthesis, as well as running equipment for tablet compression, coating, and packaging, requires large amounts of energy. Fluctuations in local energy prices can directly impact production costs.

Utility Management: Efficient management of utilities such as electricity, water, and gas is critical for controlling production costs. Implementing energy-saving technologies, recycling waste heat, and optimizing utility usage can help lower energy expenses.

Reducing energy consumption through improved process design and the use of energy-efficient equipment can lead to significant cost savings in amlodipine production.

4. Labor and Operational Costs

Labor represents a major cost factor in amlodipine production, particularly in regions with higher wages and stricter labor regulations. Skilled workers are needed to oversee production, ensure compliance with regulatory standards, and maintain quality control throughout the manufacturing process.

Labor Costs: In areas with high labor costs, pharmaceutical companies must focus on improving operational efficiency to minimize the impact on production expenses. Automating parts of the production process, where feasible, can reduce reliance on manual labor and improve efficiency.

Operational Costs: Routine operational expenses, including equipment maintenance, facility management, and safety monitoring, also contribute to the overall cost of production. Minimizing downtime and ensuring smooth workflows are essential for reducing operational expenses.

Streamlining operational processes and investing in automation can help pharmaceutical manufacturers reduce labor costs and improve overall production efficiency.

5. Quality Control and Regulatory Compliance

As a pharmaceutical product, amlodipine must meet stringent regulatory standards set by agencies such as the U.S. FDA, European Medicines Agency (EMA), and other national health authorities. Compliance with these regulations is essential for ensuring patient safety and avoiding costly recalls or legal issues.

Quality Control: Each batch of amlodipine must undergo rigorous testing to ensure that it meets the required specifications for purity, potency, and dissolution. Quality control testing includes stability testing, bioequivalence studies, and validation of the manufacturing process.

Regulatory Compliance: Compliance with Good Manufacturing Practices (GMP) is mandatory for pharmaceutical manufacturers. Maintaining GMP certification involves regular inspections, audits, and documentation, all of which add to production costs. Failure to comply with regulatory standards can result in fines, legal action, and reputational damage.

Investing in advanced quality control systems and maintaining regulatory compliance are essential for ensuring the safety and efficacy of amlodipine while minimizing production costs.

6. Environmental and Sustainability Considerations

Pharmaceutical companies are increasingly under pressure to adopt sustainable manufacturing practices that minimize environmental impact. This includes reducing waste, improving energy efficiency, and managing emissions from chemical processes.

Waste Management: The synthesis of amlodipine generates chemical waste that must be properly treated and disposed of to minimize environmental damage. Implementing green chemistry practices and optimizing solvent recovery can help reduce waste and lower disposal costs.

Sustainability Initiatives: Companies that invest in sustainable production methods, such as energy-efficient equipment and renewable energy sources, may face higher upfront costs but benefit from long-term savings and improved environmental compliance.

Investing in sustainability initiatives can not only reduce production costs over time but also enhance a company’s reputation as a responsible corporate entity.

How Procurement Resource’s Amlodipine Production Cost Reports Can Help

At Procurement Resource, we provide detailed Amlodipine Production Cost Reports to help pharmaceutical companies optimize their production processes and reduce expenses. Our reports offer a comprehensive analysis of the key factors influencing amlodipine production costs and provide actionable insights for improving efficiency.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/amlodipine/ask-an-analyst

Here’s how our reports can benefit your business:

1. Comprehensive Cost Breakdown

Our reports provide a complete breakdown of the costs associated with amlodipine production, including raw materials, labor, energy, and operational expenses. This allows businesses to identify areas where costs can be reduced.

2. Real-Time Data and Market Trends

We provide up-to-date data on market trends, raw material prices, and global demand, helping you anticipate changes and adjust your strategies accordingly.

3. Benchmarking and Efficiency Comparisons

Our reports offer benchmarking data that allows you to compare your production costs with industry standards. This helps you identify areas for improvement and potential efficiency gains.

4. Procurement Strategies

Our expert analysts provide procurement strategies to help you manage raw material costs and improve your supply chain efficiency. By closely monitoring market trends, you can make better purchasing decisions and reduce input costs.

5. Customized Solutions

Our reports are fully customizable to meet your specific business needs. Whether you're looking to optimize energy use, improve process efficiency, or reduce waste, our tailored solutions provide the insights you need to succeed.

Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/amlodipine/request-sample

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: [email protected]

Toll-Free Numbers:

USA & Canada: +1 307 363 1045

UK: +44 7537171117

Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA