In environments where noise levels are a health concern, protecting workers’ hearing is crucial. Earplugs are a common solution, but how can you be sure they’re providing the intended level of protection? Enter quantitative fit testing for earplugs, a scientific approach to ensure opti

What is Quantitative Fit Testing for Earplugs?

Quantitative fit testing is a method of measuring how effectively an earplug reduces noise exposure for an individual. Unlike qualitative methods, which rely on subjective assessments, quantitative testing uses advanced technology to provide objective, data-driven results. This ensures a precise understanding of how well earplugs perform in real-world conditions.

How Does Quantitative Fit Testing Work?

Quantitative fit testing involves specialized equipment to assess the attenuation—the reduction in noise levels—provided by the sleep earplug. The process typically includes:

- Inserting the Earplugs: The subject inserts the earplugs as they normally would in the workplace.

- Measuring Sound Levels: A microphone or probe inside the ear canal measures the noise levels both with and without the earplug.

- Calculating Attenuation: The equipment calculates the difference in decibel levels, providing a Personal Attenuation Rating (PAR).

The results help determine whether the earplugs fit correctly and provide sufficient noise protection for the individual.

Why is Quantitative Fit Testing Important?

1. Ensures Compliance with Safety Standards

Occupational safety organizations, such as OSHA in the U.S., require effective hearing protection in environments with high noise levels. Quantitative fit testing provides verifiable data to ensure compliance with regulations.

2. Personalized Protection

Everyone’s ear canal shape and size are unique. Quantitative testing ensures that earplugs are tailored to the individual, offering maximum protection.

3. Reduces Hearing Loss Risks

Inadequately fitted earplugs can leave workers vulnerable to noise-induced hearing loss (NIHL). Quantitative fit testing identifies gaps in protection, mitigating this risk.

4. Improves Workplace Productivity

Effective hearing protection reduces distractions caused by excessive noise, helping employees stay focused and safe.

Technologies Used in Quantitative Fit Testing

Several systems are designed to facilitate quantitative fit testing. Commonly used technologies include:

- Microphone-in-Real-Ear (MIRE): Measures sound levels inside the ear canal.

- Field Attenuation Estimation Systems (FAES): Provide on-site assessments of earplug effectiveness.

- Fit Validation Systems: Integrated with earplug manufacturing, these tools guide users to achieve proper insertion and fit.

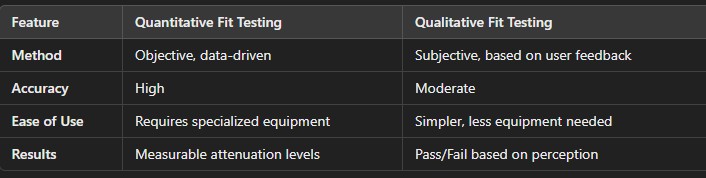

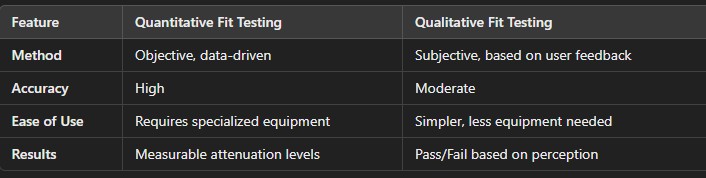

Quantitative Fit Testing vs. Qualitative Fit Testing

While qualitative methods are faster and cheaper, quantitative fit testing is far superior in accuracy and reliability.

Best Practices for Implementing Quantitative Fit Testing

- Train Employees: Workers should understand how to insert earplugs correctly and the importance of a proper fit.

- Choose Reliable Equipment: Invest in certified fit-testing systems to ensure precise results.

- Perform Regular Testing: Periodic assessments ensure earplugs continue to provide effective protection over time.

- Document Results: Maintain records of fit-testing results to comply with regulatory standards.

Conclusion

Quantitative fit testing for earplugs is a game-changer for hearing protection in noisy workplaces. By providing accurate, individualized results, it ensures that employees receive the protection they need to prevent hearing loss and stay safe. For businesses committed to workplace safety, investing in quantitative fit testing is a smart and responsible choice.

Make hearing protection a priority—because when it comes to safety, precision matters.