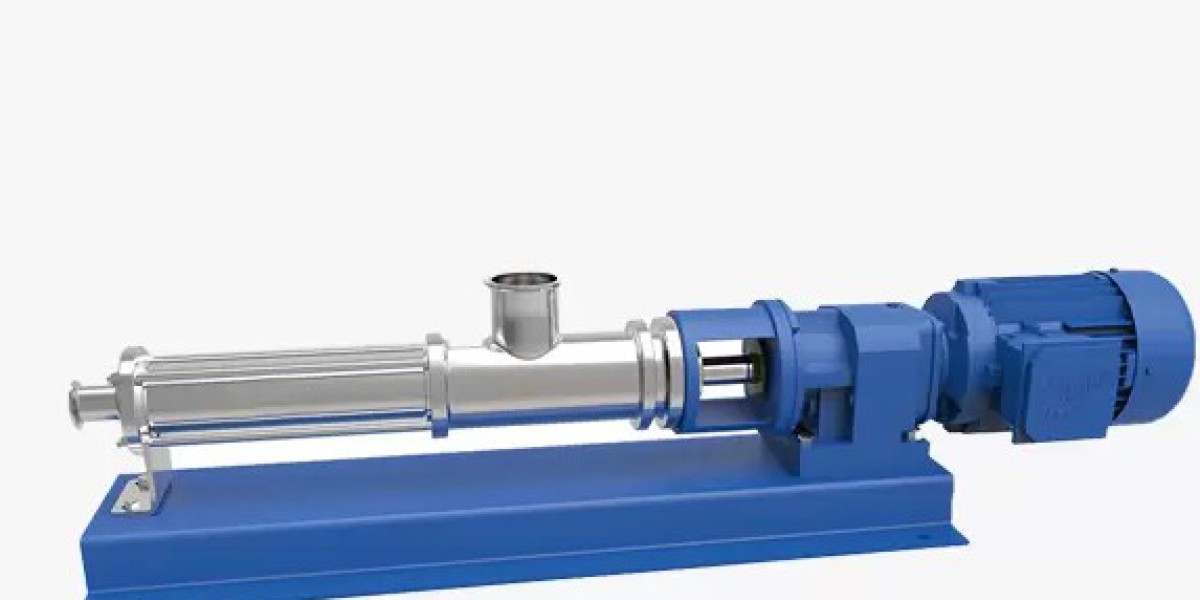

Progressive cavity pumps are renowned for their efficiency and versatility, making them a popular choice across various industries. However, like any mechanical device, they are not immune to wear and tear. One of the critical components susceptible to damage is the stator. Understanding the reasons behind stator damage and how to address them can significantly extend the life of your pump and ensure consistent performance.

What Are Stator Pumps?

Stator pumps, specifically progressive cavity pumps, operate using a rotor and stator mechanism. The rotor, typically a helical screw, rotates within the stator, which is made from a flexible material. This action creates cavities that move fluid through the pump with minimal pulsation. While this design is highly efficient, it also means that the stator is constantly in motion and contact with the rotor, making it prone to wear and damage over time.

Common Causes of Stator Damage

Stator damage can be caused by various factors, ranging from operational issues to material wear. Here are some of the most common reasons:

Abrasion and Wear

Abrasion is one of the primary causes of stator damage. When the pumped fluid contains abrasive particles, these can erode the stator's material, leading to premature wear. Over time, this wear can become significant enough to affect the pump's efficiency and cause leakage or failure.

Chemical Degradation

Chemical degradation occurs when the stator material reacts with the pumped fluid. Certain chemicals can cause the stator material to swell, harden, or become brittle, compromising its integrity and performance. It is crucial to choose stator materials compatible with the fluids being pumped.

Thermal Stress

Thermal stress results from high operating temperatures. Excessive heat can cause the stator material to degrade, lose elasticity, and crack. Ensuring proper cooling and selecting materials designed to withstand high temperatures can mitigate thermal stress.

Incorrect Assembly or Installation

Improper assembly or installation can also lead to stator damage. If the rotor and stator are not correctly aligned, uneven wear can occur, leading to premature failure. Following manufacturer guidelines and ensuring precise assembly can prevent such issues.

Overpressure and Cavitation

Operating the pump beyond its designed pressure limits can cause excessive stress on the stator, leading to deformation or rupture. Additionally, cavitation— the formation of vapor cavities in the fluid— can create shock waves that damage the stator. Maintaining proper operating conditions is essential to avoid these problems.

Solutions and Preventative Measures

Addressing stator damage involves both corrective actions and preventative measures. Here are some strategies to ensure the longevity and reliability of your progressive cavity pump:

Regular Maintenance and Inspection

Implementing a routine maintenance schedule is critical. Regular inspections can identify early signs of wear or damage, allowing for timely intervention. This proactive approach can prevent minor issues from escalating into major failures.

Material Selection

Choosing the right stator material is essential. Different materials offer varying degrees of resistance to abrasion, chemicals, and temperature. Consult with your pump manufacturer to select the most suitable material for your specific application.

Proper Installation and Alignment

Ensuring correct installation and alignment of the rotor and stator can prevent uneven wear. Use precision tools and follow the manufacturer’s guidelines during assembly. Regularly check alignment as part of your maintenance routine.

Monitoring Operating Conditions

Keeping an eye on operating conditions such as pressure, temperature, and flow rate can help maintain the pump within its optimal parameters. Implement sensors and automated systems to monitor these conditions in real time.

Using Compatible Fluids

Always use fluids that are compatible with the stator material. Consult the pump’s chemical compatibility chart to avoid any adverse reactions that could lead to degradation or swelling of the stator.

Training and Education

Ensure that all personnel involved in the operation and maintenance of the pump are well-trained. Understanding the intricacies of the pump's design and operation can lead to better handling and fewer errors that could cause damage.

Case Study: A Real-World Example

Let's consider a real-world example where a company experienced repeated stator failures in their progressive cavity pumps. Upon investigation, it was found that the pumped fluid contained a high concentration of abrasive particles, and the stator material was not suited for such conditions.

By switching to a more abrasion-resistant stator material and implementing a filtration system to remove particles from the fluid, the company significantly extended the life of their stators. Additionally, they introduced regular maintenance checks, which helped identify and address issues before they led to failures. This case study highlights the importance of selecting the right materials and maintaining proper operating conditions to prevent stator damage.

FAQ

| Question | Answer |

|---|---|

| How often should I inspect my stator pump? | Regular inspections should be conducted at least once a month, but more frequent checks are recommended for high-demand applications. |

| What signs indicate stator damage? | Common signs include reduced pump efficiency, unusual noises, leaks, and visible wear or cracks on the stator surface. |

| Can I repair a damaged stator, or does it need to be replaced? | Minor damage can sometimes be repaired, but in most cases, replacing the stator is the best solution to ensure optimal performance. |

| What materials are best for stators? | The best material depends on the application. Common materials include elastomers like NBR, EPDM, and FKM, each offering different resistance properties. |

Conclusion

Understanding the causes and solutions for stator damage in progressive cavity pumps is crucial for maintaining their efficiency and longevity. By implementing regular maintenance, choosing the right materials, and ensuring proper operating conditions, you can prevent damage and ensure reliable performance. For more information on rotor and stator pumps, check out this detailed guide on rotor and stator pump troubleshooting.