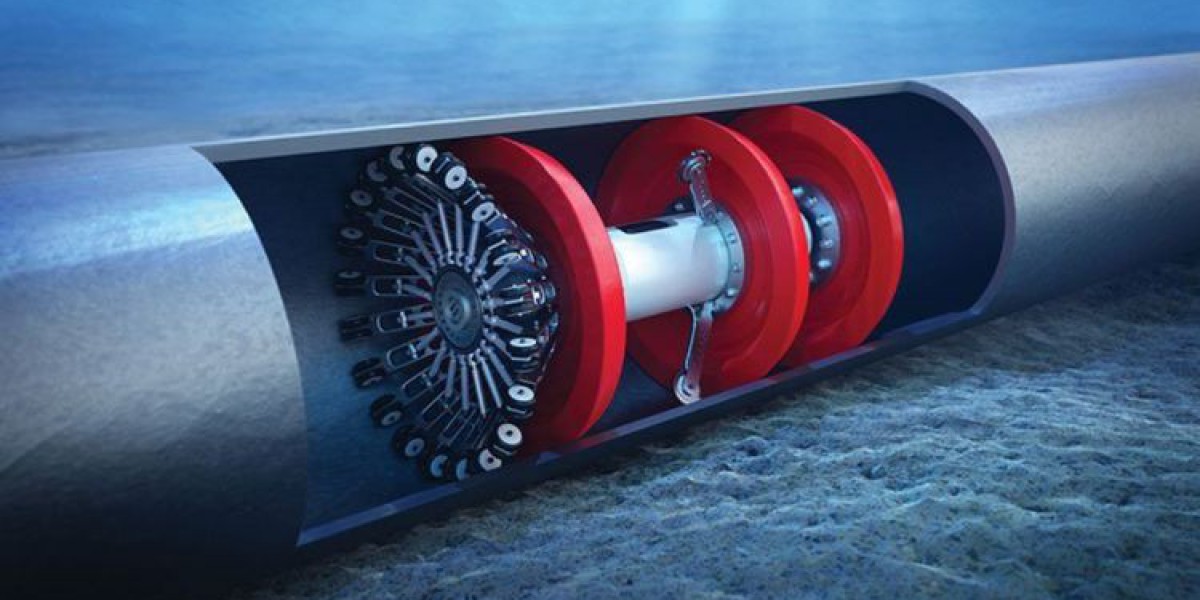

The global Intelligent Pigging Market Size, valued at approximately USD 744.55 million in 2021, is poised for significant growth. With an anticipated compound annual growth rate (CAGR) of 5.4% from 2024 to 2032, the market is expected to reach around USD 1,008.90 million by 2027. Intelligent pigging refers to the use of advanced pipeline inspection gauges (pigs) equipped with sophisticated technology to inspect and maintain pipelines. These tools are essential for the oil and gas industry, ensuring the integrity and safety of pipeline systems.

Key Benefits

- Enhanced Pipeline Integrity: Intelligent pigging systems detect anomalies such as corrosion, cracks, and deformation, allowing for timely repairs and preventing potential failures.

- Improved Safety: By identifying and addressing pipeline issues before they lead to leaks or ruptures, intelligent pigging enhances the safety of pipeline operations and reduces environmental risks.

- Cost Efficiency: Early detection of pipeline problems minimizes repair costs and operational downtime, leading to significant cost savings in maintenance and repair activities.

- Regulatory Compliance: Intelligent pigging helps companies comply with industry regulations and standards by providing accurate and comprehensive inspection data.

Key Industry Developments

- Technological Advancements: The integration of Internet of Things (IoT) and artificial intelligence (AI) with intelligent pigging systems has led to more accurate and real-time data analysis, enhancing overall performance.

- Increased Adoption: The growing demand for efficient and reliable pipeline inspection solutions has led to increased adoption of intelligent pigging technology across various industries, including oil and gas, chemicals, and utilities.

- Market Expansion: Companies are expanding their product portfolios and geographical reach to cater to the growing demand for intelligent pigging solutions in emerging markets.

Driving Factors

- Growing Pipeline Infrastructure: The expansion of pipeline networks globally, driven by increasing energy demands and infrastructure development, fuels the demand for intelligent pigging solutions.

- Rising Safety and Environmental Concerns: Increasing awareness of environmental and safety issues associated with pipeline operations drives the need for advanced inspection technologies.

- Technological Advancements: Innovations in sensor technology, data analytics, and wireless communication enhance the capabilities of intelligent pigging systems, making them more attractive to end-users.

COVID-19 Impact

The COVID-19 pandemic had a mixed impact on the intelligent pigging market. While the initial disruptions in supply chains and project delays affected market growth, the pandemic highlighted the importance of maintaining pipeline integrity and safety. The increased focus on remote monitoring and data analysis during the pandemic accelerated the adoption of intelligent pigging technologies, driving market recovery and growth.

Restraining Factors

- High Initial Costs: The high upfront investment required for intelligent pigging systems can be a barrier for small and medium-sized enterprises (SMEs), limiting market growth.

- Complexity of Implementation: The integration of advanced technologies into existing pipeline systems can be complex and time-consuming, posing challenges for widespread adoption.

- Regulatory Challenges: Navigating the regulatory landscape and ensuring compliance with varying standards across different regions can be challenging for companies operating in the intelligent pigging market.

Market Segmentation

By Technology:

- Magnetic Flux Leakage (MFL): Utilizes magnetic fields to detect corrosion and metal loss.

- Ultrasonic Testing (UT): Employs high-frequency sound waves to inspect pipeline walls.

- Radiographic Testing (RT): Uses X-rays or gamma rays to examine pipeline integrity.

- Other Technologies: Includes technologies such as laser scanning and acoustic emission testing.

By Application:

- Oil and Gas: Pipeline inspection for oil and gas transportation and distribution.

- Chemicals and Petrochemicals: Maintenance and inspection of pipelines in chemical processing industries.

- Water and Wastewater: Monitoring and inspection of water and wastewater pipelines.

By End-User:

- Energy Sector: Oil and gas companies, energy utilities.

- Industrial Sector: Chemical manufacturers, petrochemical companies.

- Government and Regulatory Bodies: Ensuring pipeline safety and compliance.

Market Outlook

The intelligent pigging market is expected to experience steady growth due to the increasing focus on pipeline safety, the expansion of pipeline infrastructure, and technological advancements. The market is likely to benefit from the rising adoption of intelligent pigging systems in emerging economies and the continuous development of new technologies.

Trends

- Integration of AI and IoT: The incorporation of AI and IoT into intelligent pigging systems is driving innovation and improving data accuracy and analysis.

- Emphasis on Remote Monitoring: The shift towards remote monitoring and data analysis is becoming a key trend, driven by the need for real-time insights and reduced operational costs.

- Sustainability Focus: There is a growing emphasis on sustainable and eco-friendly pipeline inspection solutions, aligning with global environmental goals.

Industry Segmentation

- Geographical Analysis:

- North America: Dominates the market due to the extensive pipeline infrastructure and stringent safety regulations.

- Europe: Experiences growth driven by regulatory requirements and increasing investments in pipeline maintenance.

- Asia Pacific: Represents a significant growth opportunity due to rapid infrastructure development and rising energy demands.

- Latin America: Shows potential for growth with ongoing pipeline projects and investments in energy infrastructure.

- Middle East and Africa: The region is expanding its pipeline networks, driving the demand for intelligent pigging solutions.

Analysis and News

Recent news in the intelligent pigging market highlights advancements in sensor technologies and data analytics. Companies are focusing on developing more advanced and cost-effective solutions to meet the growing demand for pipeline inspection and maintenance. Partnerships and collaborations between key players are also shaping the market landscape.

Top Impacting Factors

- Technological Innovations: The development of advanced inspection technologies and data analytics capabilities.

- Regulatory Compliance: Stringent regulations driving the adoption of intelligent pigging solutions.

- Infrastructure Expansion: Growth in pipeline infrastructure boosting the demand for inspection technologies.

Major Key Players

- T. D. Williamson, Inc.

- ROSEN Swiss AG

- Enduro Pipeline Services, Inc.

- Intertek Group plc

- Applus Services, S.A.

- LIN SCAN

- Dexon Technology PLC

Opportunities

- Emerging Markets: Expanding pipeline infrastructure in developing regions presents significant growth opportunities.

- Technological Advancements: Innovations in inspection technologies and data analysis offer opportunities for new product development and market expansion.

- Regulatory Changes: Evolving regulations and standards provide opportunities for companies to offer compliant solutions.

Challenges

- High Initial Costs: The high cost of advanced intelligent pigging systems can be a challenge for market penetration.

- Complex Implementation: Integrating new technologies into existing pipeline systems can be complex and challenging.

- Regulatory Compliance: Navigating diverse regulatory requirements across regions can pose challenges for global market players.

Scope

The intelligent pigging market encompasses a wide range of technologies and applications aimed at improving pipeline inspection and maintenance. With ongoing technological advancements and increasing focus on pipeline safety and environmental sustainability, the market is expected to continue evolving and growing in the coming years.